Actuator & Control Panel

Actuator & Control Panel

We make products that meet your needs.

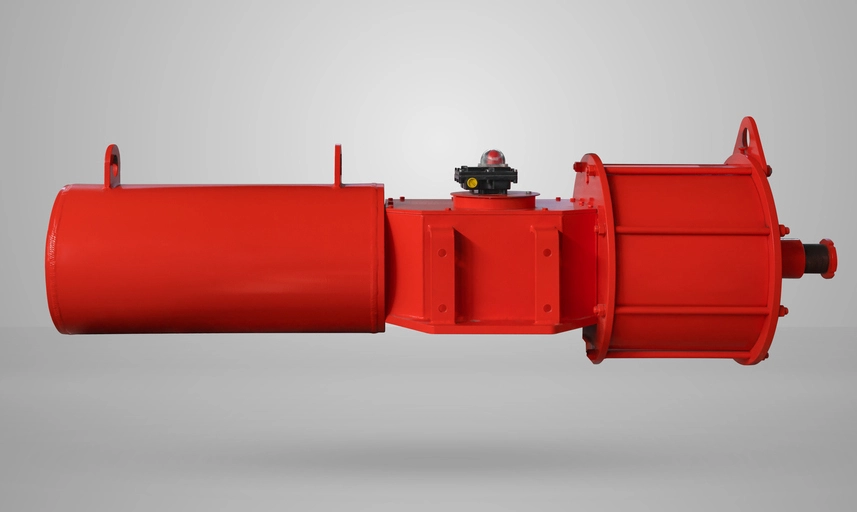

Scotch-yoke actuators are mechanisms that transform the linear movement of the hydraulic/pneumatic cylinder into a 90° rotation by engaging some internal parts such as sliding block, guide bar and guide block. These actuators are suitable for opening/closing any quarter turn valve.

The driving mechanism of an actuator is a symmetric or a canted scotch yoke which has a parabola torque output curve. This type of torque curve is proved to be the most suitable one for pipeline ball valves. Canted scotch yoke actuators are ideally suited to the larger valve sizes where high break away torques are required or for valves with high working pressure.

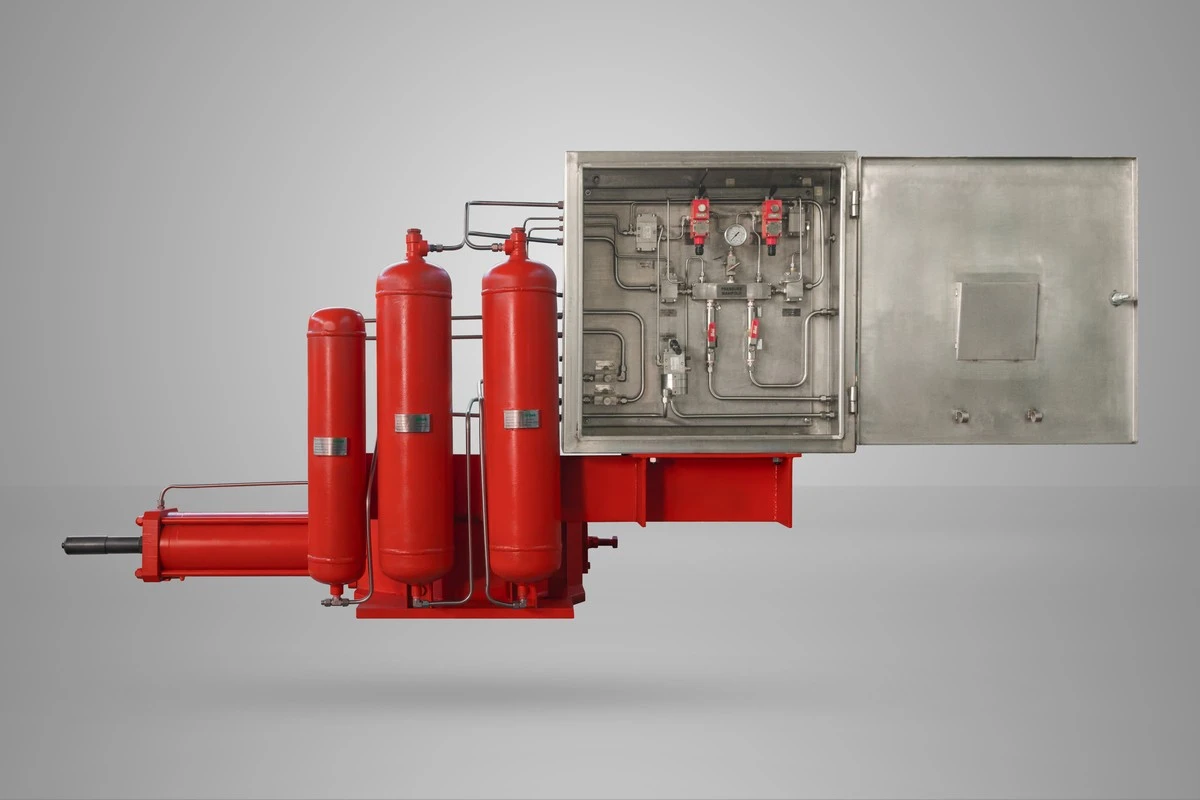

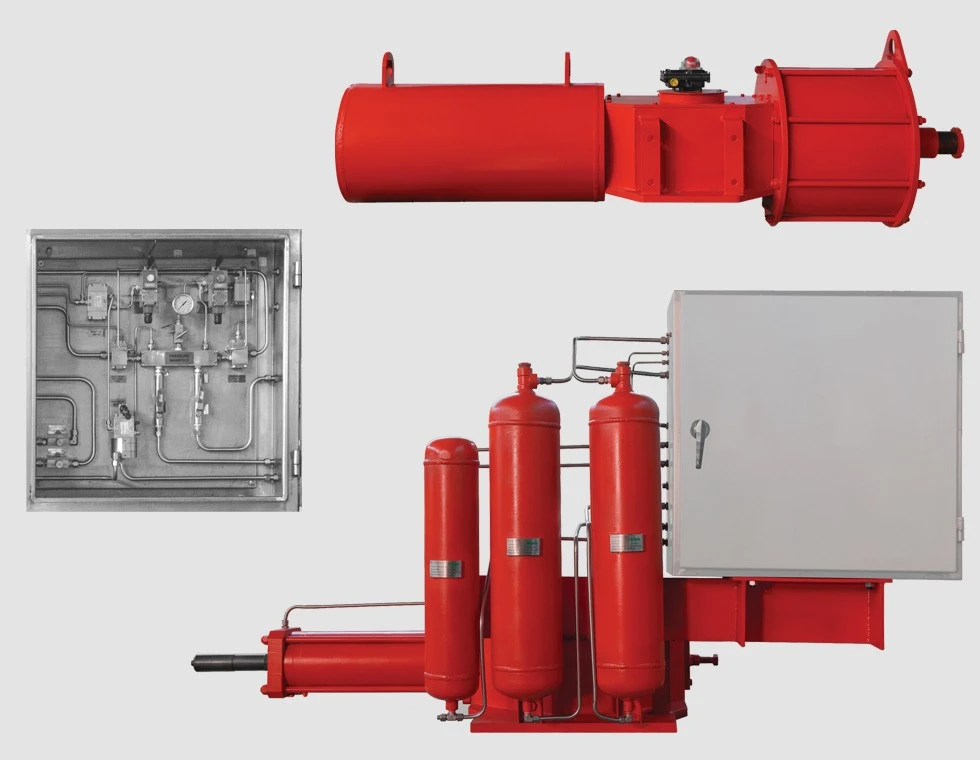

One type of actuators is gas-over-oil actuators. In gas-over-oil actuators, the gas flowing in the pipeline is used as a power source. Each actuator is also provided with a connection port to be fed by a separate supply line from a gas storage unit or by bottled gas. The gas-over-oil actuator is engineered and manufactured to work with a pressure supply varying from 7 bar to 105 bar.

The gas-over-oil actuator is fed by pressurized gas which, after being filtered, flows through the control valves into the tank relevant to the operation (opening or closing) to be performed.

The hydraulic oil contained in the tank is pressurized by the gas and flows into the relevant cylinder chamber, while the oil contained in the other chamber flows into the second tank. The cylinder piston stroke causes the actuator operation.

The oil flow from the cylinder into the tanks is adjusted by means of two flow control valves.

In this way it is possible to adjust the stroking time of the actuator.

Emergency manual override can be performed by selecting the opening and closing operation by means of the hand actuated directional control valve and then actuating the hand pump.

This type of actuator can provide up to 300,000 Nm torque which depend on the pipeline pressure and diameter of hydraulic cylinder.

Another type of actuators is single acting spring return actuators. The actuator is made up of a weatherproof scotch yoke mechanism transforming the linear movement of the pneumatic cylinder and of the spring into the rotary movement, which is necessary for operation.

The spring return pack can incorporate up to four springs, fully encapsulated in a factory welded cartridge. This ensures safety to personnel and simplifies assembly. The spring action can be easily changed in the field from “to close” in “to open” or vice versa (modular design).

Products focused on the industry!

Line Break Valve (LBV)

Line Break Valve System is specially designed to prevent sudden pressure drops at the oil and natural gas lines in major leak or break. Line break actuator can be used with all control valves, as local or remote controlled. It runs using the lines own pressure in Natural Gas Lines.

Line Break Valve system eliminates the extreme pressure changes by measuring the speed of pressure decrease using a device called “DP sensor” or “Line break device. “

The actuator will close the valve automatically when the “speed of pressure decrease” is over the adjusted value. When the system automatically performs its Line Breaking function, the ‘reset valve’ turns itself to the set position and prevents opening the valve. To re-open the valve, first the line should come back to its normal operating conditions and after making sure of that an authorized person should reset the actuator at the control panel to the initial condition. Line Break Device measures the speed of the pressure change, not the pressure itself. Let’s say while the line is in its normal operating pressure, when a leakage occurs in the line, or a pipe is broken, the system will recognize the pressure loss at the line and secures the line by shutting the valve. It is preferably set to close in less than 45 seconds for valves smaller than 30 inches in size and less than two minutes for valves larger than 32 inches in size.

The driving mechanism of actuator is a symmetric or a canted scotch yoke which has a parabola torque output curve. This type of torque curve is proved to be the most suitable one for pipeline ball valves. The Scotch Yoke mechanism is a reciprocating motion mechanism, converting the linear motion of a hydraulic/pneumatic cylinder in to rotary motion of the yokes by engaging some internal parts such as sliding block, guide bar and guide block. The Scotch Yoke actuator produces enough torque to turn a quarter-turn valve in suitable time.

You can download all the technical information of the Actuator & Control Panel in PDF file

Types of multiple control panel Sarchahi Palashgah (WHCP) Kardanan Shargh

Variety of Well Control Panel (MCCP)

Electrical Wellhead Control Panel

Multi Wellhead Control Panel (MWHCP): This wellhead control panel is usually used for offshore oil and gas fields. These units are designed as removable modules and generally include DHSV supply and return tanks, electric hydraulic pumps, accumulators, pressure regulators, hand pumps, filters and associated controls and structures for both LP supply hydraulic headers and HP hydraulic supply headers. Is. The well control panel is designed as a completely closed assembly with a hydraulic power supply unit that provides a common source of hydraulic power for each well control module.

Multi Wellhead Control Panel

Kardanan Shargh Company respects the dignity and high value of human beings and believes that human power is the main asset and the source of any transformation and change, taking advantage of the knowledge and capabilities of internal resources to employ expert and experienced personnel. And by using local knowledge, he succeeded in obtaining a knowledge-based certificate from the Vice President of Science, Technology and Knowledge-Based Economy.