High-Integrity Pressure Protection System (HIPPS)

Emergency Shut Down Valves (ESDV)

High-Integrity Pressure Protection System (HIPPS)

HIPPS

We make products that meet your needs.

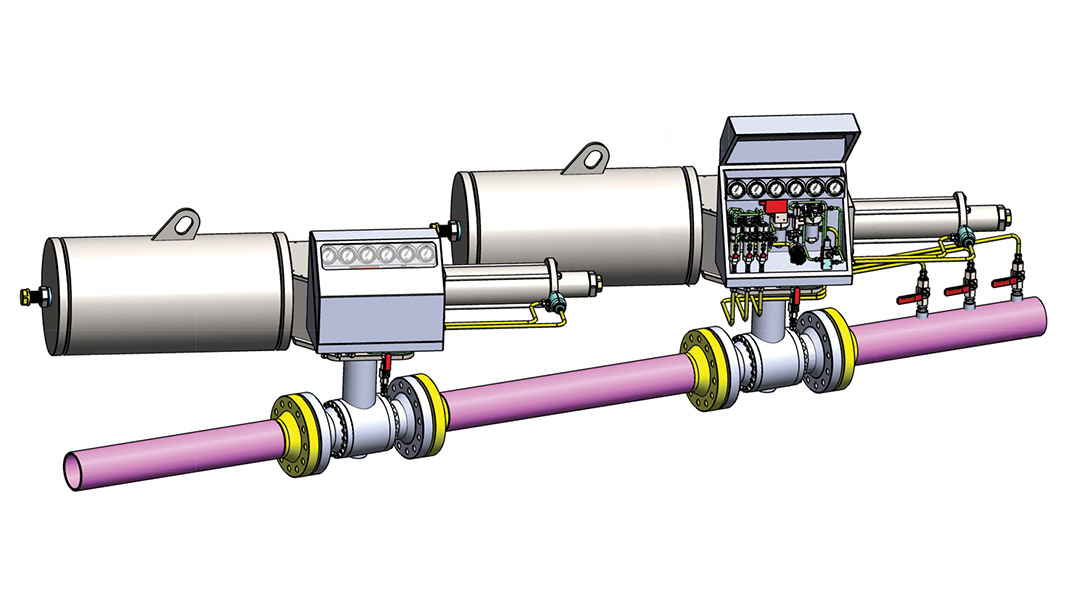

When operating in high-pressure environments and production fields, an overpressure event can cause damage to the environment, infrastructure, and personnel. Mitigating that risk on production wells and flowlines is a challenge that can be met with a HIPPS.

A system that closes the source of overpressure within the required timeframe and incorporates redundancy within the initiators (pressure sensors), logic solver, and final elements (shutdown valves) with at least the same reliability as a safety relief valve is usually identified as a HIPPS.

ESDV

Emergency Shut Down Valves

We make products that meet your needs.

The hydraulic (mechanical) HIPPS provides a self-contained, independent protection system operated on demand with one-out-of-two (1oo2) or two-out-of-three (2oo3) (voting) pressure sensor inputs, a hydraulic logic solver, and two spring-return hydraulically actuated safety valves. The unit is typically self-powered and can be provided with additional real-time controls via a hydraulic power unit (HPU). This pressurizes the system and opens the safety shutdown valves.

The system remains open (armed) until an abnormal condition is detected. If an abnormal condition is detected, then the system closes the two actuated final element valves, protecting the downstream production or facility.

Our innovations

Products focused on the industry!

Applications

- Wellhead flowline

- Pipeline and compressor stations

- Flaring systems

- Separation and processing facilities

- Gas plants

- Gas storage

- Floating production storage and offloading (FPSO) vessels

- Offshore platforms

- Onshore operations

Key Features & Standards

- High-integrity, flexible mechanical and electronic design

- Pneumatic and hydraulic actuator options (conventional or compact)

- Self-contained hydraulic system

- Partial- or full-stroke testing

- Size 6 inches to 36 inches

- requirements for the specification, design, installation, operation and maintenance of a safety instrumented system (SIS) according to IEC 61511-1: standard

- SIL 3 certified design according to IEC 61508 standard

- Specifies requirements for the attachment of part-turn actuators according to ISO 5211 standard

- Mechanical integrity and sizing of actuators and mounting kits for pipeline valves according to API STD 6DX/ ISO 12490 standard

- Material used in H2S environment according to NACE MR0175 standard