PLEM Valve (Pipeline End Manifold)

PLEM valve

Pipeline End Manifold

We make products that meet your needs.

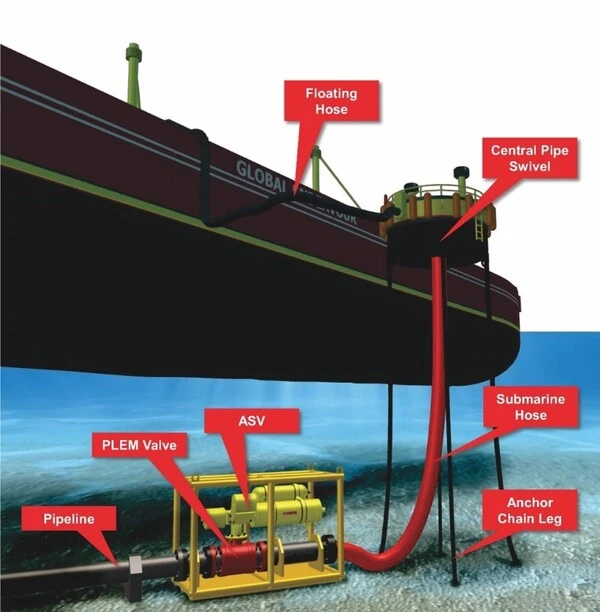

When due to shallow water depth or lack of suitable docks, it’s not feasible for ships to dock for loading oil and other derivatives, the PLEM system is utilized. This system comprises components such as the HPU and PLEM valve. The HPU is placed on a buoy or floating platform, and it connects to the PLEM valve via underwater hoses.

The PLEM valve is a crucial component in subsea oil and gas pipeline systems, typically installed at the endpoint of a pipeline, often near shores or lakes. Its primary function is to manage and control the flow of materials in the pipelines. Additionally, PLEM serves as a connection point for various transfer mediums like pipelines and boilers to marine systems such as oil tankers, offshore power plants, and other relevant organizations.

Main components:

The features of PLEM valve include:

We make products that meet your needs.

- Pressure resistance: The valve must withstand high pressures and harsh conditions in the marine environment.

- Flow control: Effectively controlling material flow to prevent material loss and mitigate issues arising from sudden flow increases or decreases.

- Maintenance capability: It should be easily repairable and maintainable to quickly address repair or replacement needs with minimal hassle.

- Safety and security: The valve should have appropriate safety features to prevent adverse incidents like leaks or explosions.

PLEM ( Pipeline End Manifold )

An HPU (Hydraulic Power Unit) is utilized to supply hydraulic power for the PLEM valves to ensure their proper control and functioning. This HPU unit typically includes equipment such as hydraulic pumps, oil reservoirs, filtration and control systems, as well as precision instruments, safety, and monitoring equipment.

The primary functions of an HPU for PLEM valves include:

- Hydraulic power supply: Providing hydraulic pressure and flow for controlling PLEM valves. This hydraulic pressure and flow are sent to the valves to control their operation, including opening and closing the valve.

- Monitoring and control: Typically equipped with advanced control and monitoring systems to supervise the performance of PLEM valves and control their status.

- Safety and reliability: An HPU should support safety equipment such as ESD systems, automatic sensors, and other safety features to ensure the safety and satisfactory performance of PLEM valves.

- Maintenance and repair: HPU should be easily maintainable and repairable to quickly address errors and issues and prevent interruptions in valve performance.