Wellhead Control Panel (WHCP)

We make products that meet your needs.

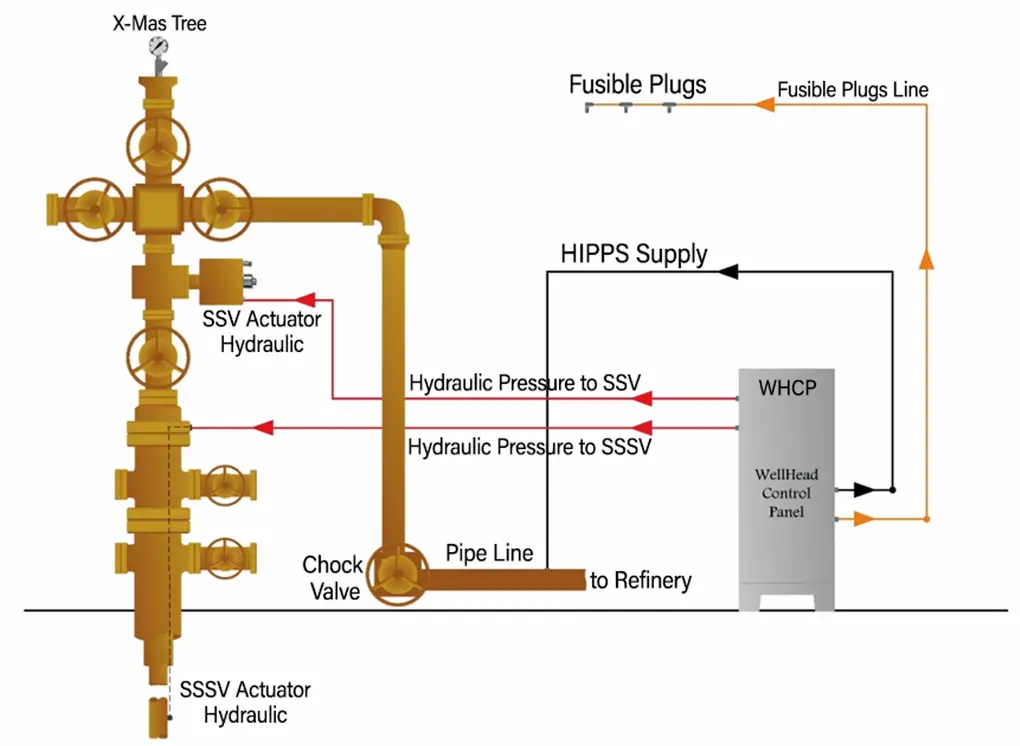

The wellhead control board is a board with a hydraulic mechanism that is responsible for opening or closing the wellhead valves of oil and gas wells. Valves include SSV (Surface Safety Valve) and SSSV (Subsurface Safety Valve).

In addition, to providing hydraulic pressure for SSV and SSSV valves, it can also provide hydraulic pressure for operation valves such as WING valve according to the needs of the client.

It can also supply the hydraulic pressure of the ESD valves of the HIPPS system in the pipeline.

The safe mechanism of opening or closing these valves is one of the most important advantages of this product. This product protects the well by controlling the pressure of the well with the precision instrument equipment it contains.

Detection of fire and explosion and safe closing of the well by the FUSIBLE PLUG line are other tasks of the well control panel.

The well control panel is available in two main types of products, the first type is SINGLE WHCP, which is capable of controlling one well and is installed on land. The second type is called MULTI WHCP, which is capable of controlling several wells at the same time and is installed in the sea and on oil platforms. SINGLE type This product is available in three types. The first type, which is called TYPICAL WHCP, is designed for areas that have access to electrical energy and uses an electro pump to create hydraulic pressure. The second type is called GAS DRIVE WHCP, which uses a GAS DRIVE pump to create hydraulic pressure and supplies its energy from nitrogen or air capsules. The third type is called SOLAR WHCP and it obtains its power from the sun to operate precision instruments.

You can download all the technical information of the well head control panel (WHCP) in PDF file

Types of WellHead Control Panel (WHCP)

Solar WellHead Control Panel

The solar Wellhead control panel provides the required electricity for precision instruments(24 volts DC) from solar energy. are designed to operate in harsh Offshore/Onshore desert environment conditions.WHCP is supplied with solar power system which contains 3 main components: Solarmodules, Charge regulator(s) & Battery bank. Solar modules are assembled on a structure& mounted on top of the panel. Solar module produces DC power and is wired through thecharge regulator to charge the battery bank. The two main functions of the chargeregulator are to prevent the battery from being overcharged and to eliminate any reversecurrent flow from the batteries back to the solar modules at night. Charge controller isprovided inside the Local Control Panel, in case of low voltage or over voltage. Itdisconnects batteries from charge circuit and as well from load circuit to protect the solarsystem. The battery bank stores the energy produced by the solar array during the day foruse at any time of day or night. Batteries come in many sizes and grades.

WHCP comes with a battery load bank according to customer’s autonomy requirement.

Well Head Control Panel (Electro-Hydraulic)

This wellhead control panel is designed to control a single well; the unit generally integrates a fixed assembly but it can be

designed as a type of module with removable drawers.

It generally includes SSSV supply and return tanks, electrically driven hydraulic pumps, accumulators,

pressure regulators, hand pump, filters and associated controls and instruments for the supply manifolds

LP hydraulics and HP hydraulic supply manifolds. In this type of WHCP, the LOW and HIGH pipeline pressures are

detected by electric pressure switches.

The wellhead control panel is designed as a fully enclosed assembly with the hydraulic power unit providing

a common source of hydraulic power for each well control module.

The simplicity or complexity of the systems depends solely on the customer’s request based on the requirements of the

project.

This type of wellhead control panels are designed to control underground safety valves (SSSV), valves

Surface Safety Valves (SSV), Wing Valves (WV) and provide hydraulic pressure for HIPPS and ESD valves. The signal

logic to control the system is hydraulic.

Multi WellHead Control Panel

This Wellhead control panel usually use for offshore oil/gas fields; these units are designed as removable drawer module type and generally comprises of supply and DHSV return reservoirs, electrically driven hydraulic pumps, accumulators, pressure regulators, hand pumps, filters and associated control and instrumentation for both, the LP hydraulic supply headers and the HP hydraulic supply headers.

The Wellhead Control Panel is designed as a fully enclosed assembly with the Hydraulic Power Unit providing a common source of hydraulic power for each well control module.

The simplicity or complexity of the systems is purely down to the clients request based on the requirements of the project.

Also PLC control systems can be considered as Instrumented Protective System (IPS) for Wellhead valves Open/Close sequence, Control, Operation and shutdown safety requirements & to meet high degree of Reliability, Availability, Functional safety and complete integrity.

These type of Wellhead Control Panels are designed for controlling the Down Hole Safety Valves (DHSV) Master Valves (MV), Wing Valves (WV), Choke Valves and Gas Lift Valves. The logic signal for controlling the system is hydraulic or pneumatic.

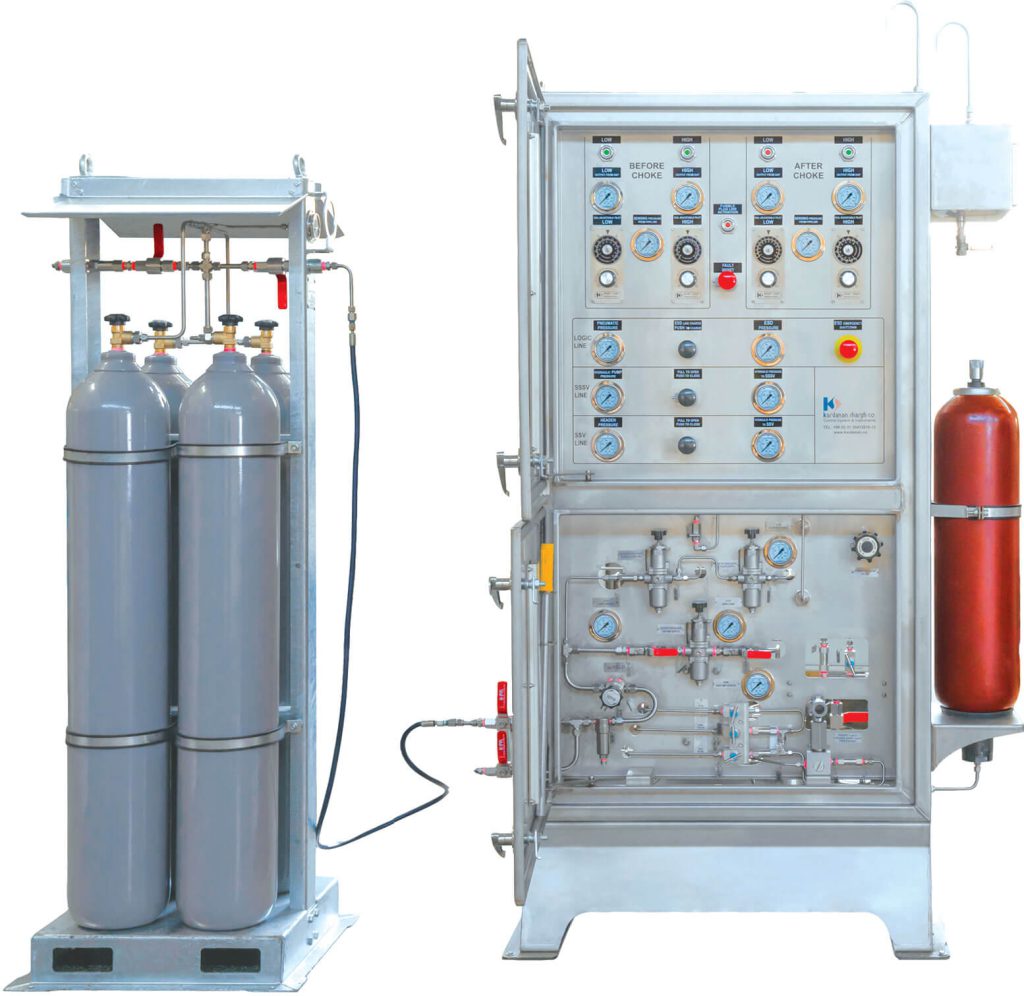

WellHead Control Panel (Air/Gas Drive )

This wellhead control panel designed to control single wells; It generally includes a feed tank,

air/gas hydraulic pumps, accumulators, pressure regulators, hand pump, filters as well as

controls and associated instruments for the LP pneumatic power manifold (logic) and HP hydraulic power manifolds. In this

type of WHCP, the LOW and HIGH pipeline pressures are sensed by mechanical adjustable pilot valves.

The panel is designed to withstand pneumatic pressures up to 150 PSI and hydraulic pressure up to 15

000 PSI. Hydraulic pressure is generated by air/gas pumps. Pneumatic pressure is supplied from cylinders to

nitrogen or air or gas rack instrumented from a pipeline. The complete panel is enclosed in a stainless steel housing

up to 3 mm thick, which encapsulates instruments and tubes.

The Wellhead control panel is designed for the highest levels of security.